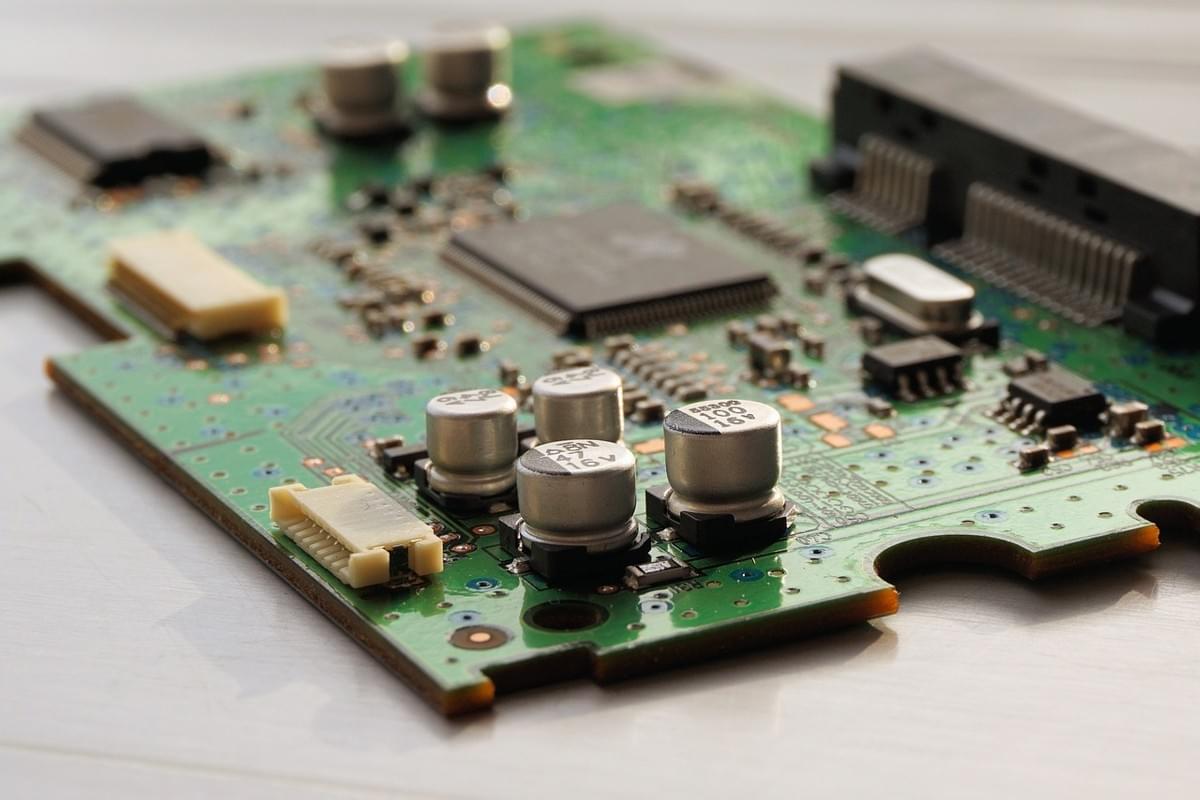

A PCB printer is the best in electronic devices as well as interactions layout. A PCB printer is a very specialized type of printer that creates computer published circuit card (PCBs) utilizing digital parts. These elements include transistors, capacitors, resistors, diodes, capacitors and piezo sound couplers. A PCB printer essentially sustains and also executes electric as well as mechanical connections in between electronic or electric parts using conductive pads, tracks and also other parts etched onto or in between numerous layer sheets of either an aluminum or copper laminate. When a PCB is printed by a PCB printer, it can be generated on a bigger range than what would certainly be possible with standard approaches of fabrication.

PCBs are not only smaller sized in scale yet are additionally a lot easier to produce. This is due to the fact that they call for less manual labor, which equates directly into less expensive costs. As discussed previously, this is because the manufacturing procedure does not call for as much manual labor. As opposed to having to manually puncture layers of material, for instance, a PCB can be made to fit the exact type needed without cutting any kind of product. This makes the whole production process much quicker as well as allows even more people to work with it. This is specifically true for huge factories, where several PCBs require to be produced on a smaller scale. Since the PCB production as well as assembly are performed in a manufacturing facility, it is less complicated to keep track of the quality and also performance of the completed product. Because each set is created in a solitary area as well as can be conveniently inspected, issues in the initial batch of PCBs can be easily determined. Click here for more information about pcb printers.

Because the production and setting up are controlled by experts, flaws are caught before they have time to spread out, resulting in less manufacturing hold-ups and a smoother production procedure on the whole. Among the biggest benefits of a PCB printer is that the final product can be standardized in high volumes. This is since a multitude of manufacturing runs can be performed at when. The more PCBs can be generated in a provided quantity, the a lot more production runs can be done at one time. This causes lowered labor expenses, due to the fact that each run can be completed in a much shorter amount of time. Since production runs can be run simultaneously, the end product is additionally simpler to handle. Due to the fact that the manufacturing can be run in a brief period of time as well as with minimal effort, it is also able to fulfill the needs of several consumers at one time. This enables the company to take on even more clients and fulfill as many of their needs as feasible. Check out this related post to get more enlightened on the topic: https://en.wikipedia.org/wiki/Printed_circuit_board_milling.